- This topic is empty.

-

AuthorPosts

-

2025-08-20 at 11:58 am #9743

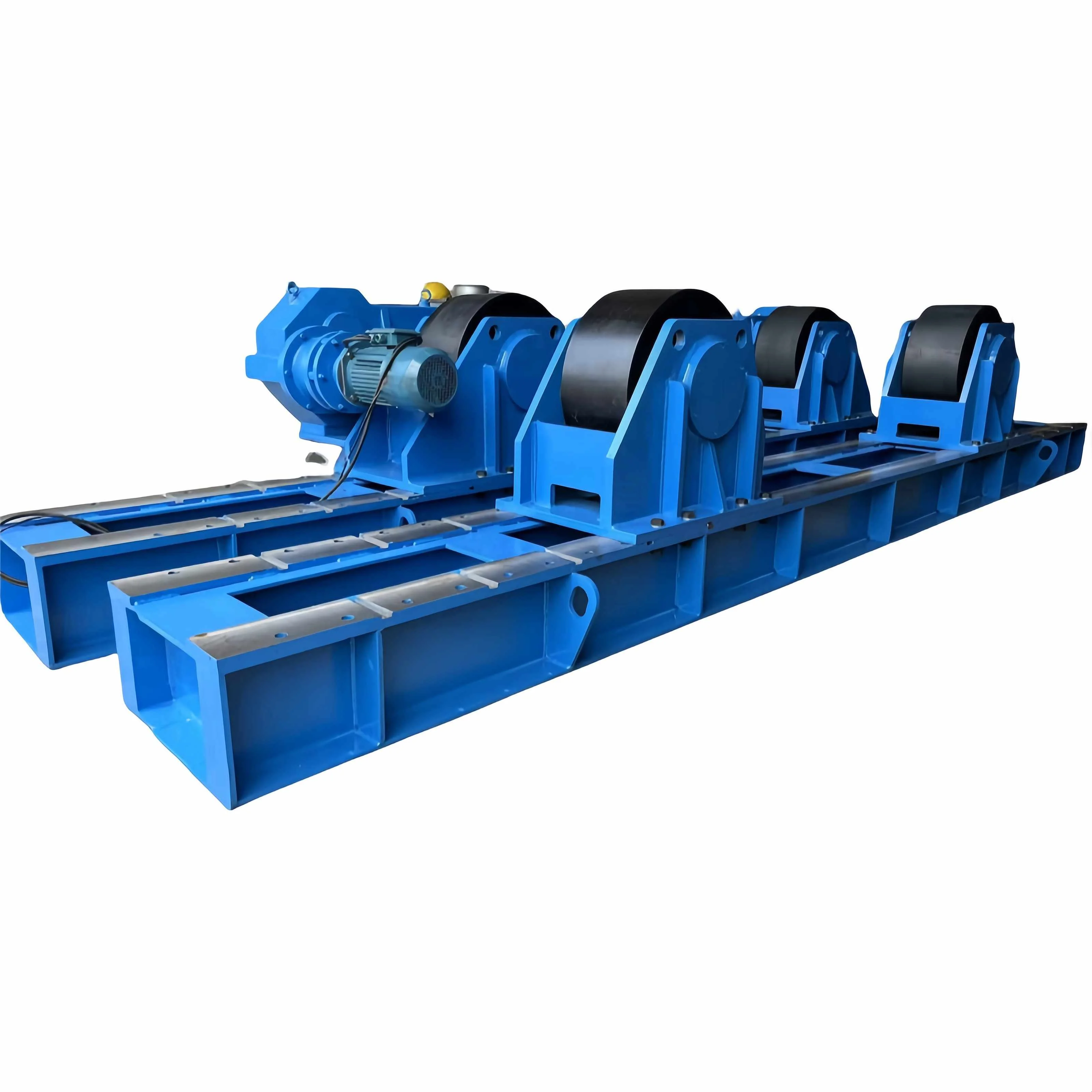

In the vast landscape of industrial equipment, the 150T bolt welding rotator stands out as a marvel of engineering, specifically designed to meet the rigorous demands of heavy-duty welding projects. Resize Machinery's150T bolt welding rotatorr is an efficient and reliable welding equipment designed for the welding and processing of heavy workpieces. Its excellent load-bearing capacity and stability enable it to easily handle workpieces weighing up to 150 tons, ensuring the accuracy and safety of the welding process. The welding rotator is equipped with an advanced control system, which is easy to operate and can adjust a variety of welding angles, greatly improving work efficiency. Whether in shipbuilding, pressure vessels or the production of large structural parts, Resize Machinery's 150T bolt welding rotator can provide excellent performance and help companies improve production capacity and product quality.

Versatile Applications Across Multiple Industries

The 150T bolt welding rotator is a testament to versatility, as it finds its place in numerous sectors including wind power, pressure vessels, petrochemicals, pipelines, steel structures, boilers, shipyards, and nuclear power. Its primary use is for welding, installation, and polishing of cylinders, making it an indispensable tool in environments where precision and strength are paramount.

-

Wind Power: In the wind energy sector, the rotator assists in the fabrication and maintenance of wind turbine towers and blades, ensuring that these structures can withstand extreme weather conditions.

-

Pressure Vessels: For the manufacture of pressure vessels, the rotator provides a stable platform for welding, ensuring the integrity and safety of these critical components.

-

Petrochemicals: In the petrochemical industry, the rotator is used for welding pipelines and tanks, where the highest standards of quality and safety are essential.

-

Pipelines: The ability to rotate large pipes and sections allows for seamless welding of pipeline segments, crucial for the transportation of oil, gas, and other fluids.

-

Steel Structures: From bridges to skyscrapers, the rotator supports the welding of steel beams and columns, contributing to the structural integrity of these monumental structures.

-

Boilers: In boiler manufacturing, the rotator facilitates the welding of heavy pressure vessels and heat exchangers, ensuring efficient and safe operation.

-

Shipyards: For shipbuilding, the rotator is essential for welding large sections of hulls and other components, helping to create robust and durable vessels.

-

Nuclear Power: In the nuclear industry, precision welding is crucial for safety. The rotator ensures accurate welds in reactor components and other critical structures.

Key Selling Points of the 150T Bolt Welding Rotator

1. Unmatched Strength and Capacity

With a capacity of 150 tons, the rotator is designed to handle the heaviest loads with ease. Its robust construction and precision engineering make it suitable for welding even the largest and most complex components.

2. Precision and Accuracy

The rotator's advanced control system allows for precise positioning and rotation, ensuring that welds are consistent and of the highest quality. This level of accuracy is crucial in industries where the margin for error is minimal.

3. Enhanced Efficiency

The ability to rotate and position large workpieces quickly and easily reduces setup time and increases productivity. This, in turn, leads to cost savings and faster completion of projects.

4. Versatility in Operations

Whether it's horizontal or vertical welding, the rotator adapts to various welding positions, making it a versatile tool for a wide range of applications. This flexibility ensures that it remains a valuable asset in diverse industrial settings.

5. Safety and Reliability

Safety is paramount in all industrial operations. The rotator is equipped with safety features such as overload protection, emergency stops, and robust guarding to ensure the safety of operators and equipment. Its reliability means fewer breakdowns and longer uptime, contributing to overall operational efficiency.

6. Easy Maintenance and Serviceability

Designed with ease of maintenance in mind, the rotator features accessible components and user-friendly diagnostics. This ensures that any issues can be quickly identified and resolved, minimizing downtime and maintaining peak performance.

Conclusion

The 150T bolt welding rotator is a game-changer in the world of heavy-duty welding projects. Its unmatched strength, precision, efficiency, versatility, safety, and reliability make it an ideal choice for industries requiring the highest standards of quality and performance. Whether you're in wind power, pressure vessels, petrochemicals, pipelines, steel structures, boilers, shipyards, or nuclear power, the Resize Machinery 150T bolt welding rotator is ready to provide a perfect solution for your heavy-duty welding needs.

https://www.resizeglobal.com/providing-a-perfect-solution-for-heavy-duty-welding-projects.html

http://www.resizeglobal.com

Resize welding machinery -

-

AuthorPosts

- You must be logged in to reply to this topic.