- This topic is empty.

-

AuthorPosts

-

2026-01-07 at 10:16 am #10754

Cleanroom space has become one of the most constrained and expensive resources in modern pharmaceutical manufacturing. As injectable drug pipelines expand and regulatory expectations tighten, global pharma manufacturers are being forced to re-evaluate every square meter of Grade A–D environments. Labeling—often treated as a downstream afterthought—has emerged as a critical bottleneck where poor equipment design can compromise both space efficiency and compliance.

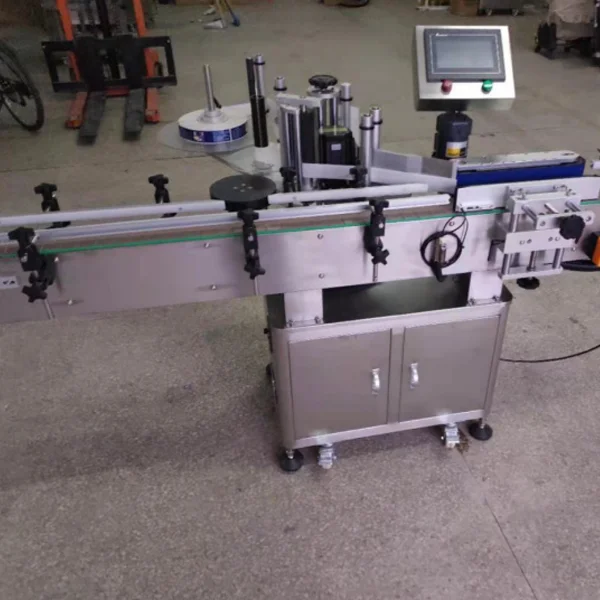

Pharmasys compact automatic labeling machines are engineered specifically for this reality. Rather than adapting general-purpose labeling equipment to aseptic environments, Pharmasys has developed a labeling architecture that aligns with cleanroom logic, high-mix pharmaceutical production, and future regulatory scalability.

This article examines how compact labeling system design directly translates into cleanroom optimization, operational resilience, and long-term compliance for global pharmaceutical enterprises operating under severe spatial constraints.

Rethinking Labeling Footprint as a Cleanroom Design Variable

In sterile and high-grade pharmaceutical environments, footprint is not merely a physical dimension—it affects airflow patterns, pressure differentials, operator movement, and contamination risk.

According to ISPE baseline guidance, inefficient equipment layouts can increase cleanroom operational costs by 15–30% over a system’s lifecycle due to HVAC load, cleaning labor, and validation complexity. Labeling machines with oversized frames, external control cabinets, or excessive buffer zones directly erode usable cleanroom capacity.

Pharmasys approaches labeling footprint reduction through mechanical integration rather than functional compromise. The compact frame design consolidates:

-

Label feeding

-

Bottle separation

-

Compression and adhesion

-

Control and HMI systems

into a unified mechanical envelope, enabling installation in tight post-filling or inspection zones without disrupting validated layouts.

Compact Design Without Sacrificing Throughput Stability

A common misconception is that compact labeling machines inherently trade stability for size. Pharmasys’ compact automatic labeling machines challenge this assumption by using servo-driven label feeding systems from premium suppliers, paired with PLC-based motion control.

This architecture enables:

-

Stable labeling at 30–60 m/min, even with short conveyor lengths

-

Consistent tension control across varying label materials

-

Reduced vibration and micro-misalignment, critical for high-resolution pharmaceutical labels

Because servo precision replaces mechanical bulk, Pharmasys eliminates the need for oversized structural components typically used to “absorb” instability in conventional machines.

Cleanroom-Friendly Mechanical Architecture

Cleanroom optimization is not only about size—it is about how equipment interacts with the environment.

Pharmasys compact labeling machines are designed with:

-

Smooth, minimalistic mechanical surfaces to reduce particle accumulation

-

Compact belt-driven systems instead of large chain mechanisms

-

Elastic cotton-polyester labeling belts that apply pressure evenly without generating particulate abrasion

These design choices support faster cleanroom wipe-down cycles and reduce the risk of requalification delays caused by contamination events.

Universal Bottle Handling Reduces Changeover Space Requirements

In multi-product pharmaceutical facilities, changeover logistics consume both time and space. Traditional labeling machines rely on extensive format parts that must be stored, transported, and sanitized—often inside or adjacent to cleanrooms.

Pharmasys eliminates much of this burden through a universal bottle separation mechanism capable of accommodating multiple diameters without part replacement. Adjustable rotary wheels further expand compatibility when required.

Operational impact includes:

-

Reduced need for cleanroom storage of change parts

-

Faster batch-to-batch transitions

-

Lower operator intervention, decreasing contamination risk

For facilities running biologics, injectables, or medical aesthetics products in short production campaigns, this directly translates into higher cleanroom utilization efficiency.

Precision Labeling as a Regulatory Safeguard

Label integrity is not a cosmetic issue in pharmaceuticals—it is a compliance requirement. Wrinkles, skew, or inconsistent adhesion can compromise barcode readability, serialization accuracy, and traceability.

Pharmasys addresses this through a rotary compression roller system combined with elastic belt labeling, ensuring uniform pressure across the container circumference. This is particularly critical for:

-

Full-circumference labeling of cylindrical vials

-

Semi-circular labeling where label edges must align precisely

-

High-gloss or specialty pharmaceutical label stocks

Industry data from GS1 indicates that labeling defects account for over 20% of packaging-related batch deviations in regulated pharmaceutical environments. Precision application reduces both deviation risk and downstream inspection rejects.

Integrated Coding Without Cleanroom Penalty

Inline coding often introduces complexity: additional space, air supply routing, and validation scope. Pharmasys compact automatic labeling machines integrate optional pneumatic or electric coding units directly into the labeling platform.

Key advantages include:

-

High-resolution batch and date coding compliant with 21 CFR Part 11

-

No need for standalone coding stations

-

Controlled air consumption at 0.5 MPa, supporting cleanroom utility planning

By embedding marking capability within the labeling footprint, Pharmasys minimizes equipment sprawl while maintaining data integrity and audit readiness.

Human-Machine Interface Designed for Aseptic Workflow

Operator interaction is a major variable in cleanroom risk. Pharmasys’ user-friendly HMI system is engineered to reduce unnecessary interaction time through:

-

Intuitive, context-aware touchscreen navigation

-

Stepless speed synchronization between labeling, conveying, and bottle spacing

-

Clear alarm diagnostics to minimize troubleshooting dwell time

This aligns with industry findings that reduced operator dwell time can lower contamination probability by up to 40% in aseptic environments, according to PDA technical reports.

Seamless Integration into Aseptic Filling Ecosystems

As a supplier specializing in core aseptic equipment for injectable drug production, Jiangsu Pharmasys Intelligent Equipment Co., Ltd. designs labeling machines that integrate naturally with:

-

Aseptic filling machines

-

Stoppering and capping systems

-

Prefilled syringe filling lines

-

Downstream conveyors and accumulation turntables

This system-level compatibility reduces layout compromises and ensures that compact labeling does not become a constraint when scaling aseptic filling capacity.

Supporting Global Compliance and Future Scalability

Global pharmaceutical enterprises operate across regulatory jurisdictions with evolving standards. Pharmasys labeling platforms are designed to support:

-

Electronic records and audit trail integration

-

Serialization and traceability expansion

-

Validation documentation aligned with FDA, EU GMP, and PIC/S expectations

Compact design, in this context, is not just about today’s cleanroom—it is about ensuring that tomorrow’s compliance upgrades do not require costly reconfiguration.

FAQ: Compact Automatic Labeling in Pharmaceutical Cleanrooms

Q1: Can compact labeling machines handle high-speed pharmaceutical production?

Yes. Pharmasys systems maintain stable labeling performance at industrial speeds through servo control and PLC synchronization.Q2: Are compact machines harder to clean and maintain?

On the contrary, reduced mechanical complexity and smooth surfaces simplify cleaning and preventive maintenance routines.Q3: How does compact design affect validation?

Smaller equipment footprints typically reduce validation scope by limiting airflow disruption and simplifying environmental qualification.Q4: Can the system adapt to future container formats?

Yes. Universal bottle handling and modular integration support future product diversification without major equipment changes.

Conclusion: Compact Labeling as a Strategic Cleanroom Asset

In modern pharmaceutical manufacturing, cleanroom space is a strategic asset—not a fixed constraint. Pharmasys compact automatic labeling machines transform labeling from a space-consuming necessity into a precision-engineered contributor to cleanroom efficiency, regulatory confidence, and operational scalability.

By aligning mechanical compactness with pharmaceutical-grade control, compatibility, and compliance, Pharmasys enables global pharma manufacturers to do more within less space—without compromise.

http://www.pharmasys-tech.com

Jiangsu Pharmasys Intelligent Equipment Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.