- This topic is empty.

-

AuthorPosts

-

2025-10-30 at 10:49 am #10259

In the world of metal alloys, 316 stainless steel strip stands out for its exceptional resistance to corrosion, high strength, and versatility in various demanding applications. Known for its excellent performance in harsh environments, 316 stainless steel strip is widely used in industries such as chemical processing, marine applications, automotive manufacturing, and medical equipment. This article Zhonggongte Metallurgical aims to explore the unique features of 316 stainless steel strip. Whether you're an engineer, manufacturer, or industrial designer, understanding the characteristics of this material can help you make informed decisions when choosing the right steel for your next project.

What is 316 Stainless Steel Strip?

The 316 stainless steel strip is a premium-grade stainless steel product valued for its exceptional corrosion resistance and mechanical strength. It is primarily composed of iron, chromium, nickel, and a crucial addition of molybdenum. The molybdenum content significantly enhances its ability to resist chloride-induced corrosion, making the 316 stainless steel strip far more durable than standard 304 stainless steel in aggressive environments.

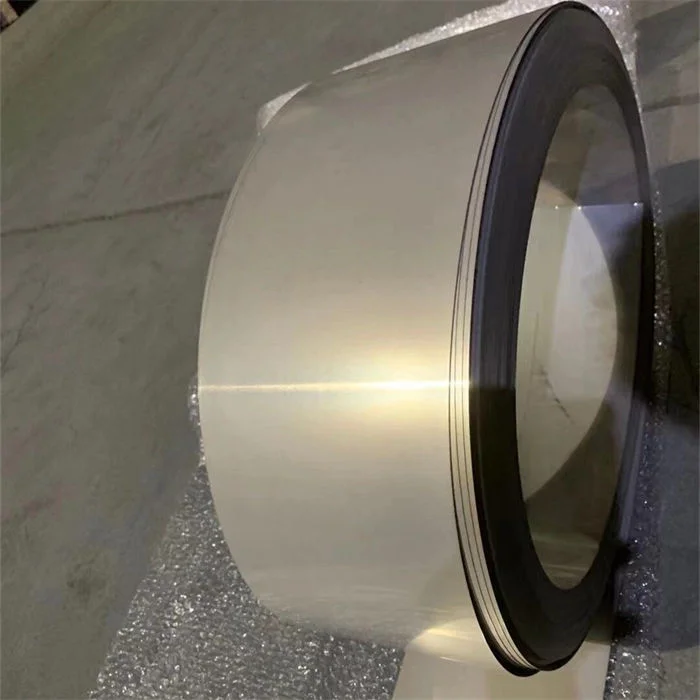

Manufactured in thin, flat strips, the 316 stainless steel strip is easy to roll, cut, and form, which provides flexibility across a wide range of industries. Available in different widths, thicknesses, and finishes, it is adaptable to applications in construction, marine environments, chemical processing, medical devices, and consumer goods. The combination of strength, durability, and superior corrosion protection makes the 316 stainless steel strip a preferred material wherever long service life and reliability are required.

Key Features of 316 Stainless Steel Strip

The 316 stainless steel strip is widely chosen because of its unique set of features that make it suitable for both industrial and decorative purposes. Its ability to withstand harsh operating conditions while maintaining aesthetic appeal sets it apart from many other stainless steel grades.

Corrosion Resistance

One of the most outstanding characteristics of the 316 stainless steel strip is its superior corrosion resistance. Thanks to the addition of 2–3% molybdenum, it resists pitting and crevice corrosion caused by chlorides, which is especially important in marine and coastal environments where saltwater exposure is constant. This property makes the 316 stainless steel strip indispensable in industries such as shipbuilding, offshore oil and gas, desalination plants, and chemical processing facilities. Unlike standard 304 stainless steel, which may show signs of rust in these conditions, the 316 grade maintains its integrity and appearance.

High Strength and Durability

The 316 stainless steel strip offers excellent tensile strength and toughness, even at thinner gauges, making it suitable for demanding structural and load-bearing applications. It performs well under heavy stress and repeated mechanical loads, demonstrating impressive fatigue resistance. These qualities ensure that the 316 stainless steel strip maintains long-term durability in industries such as automotive, aerospace, and heavy machinery. For equipment that must endure daily wear and tear, its durability minimizes maintenance requirements and extends service life.

Heat Resistance

Another valuable feature of the 316 stainless steel strip is its ability to withstand elevated temperatures without losing structural integrity. It maintains mechanical strength and oxidation resistance up to about 870°C (1600°F) in intermittent use and up to 925°C (1700°F) in continuous service. This makes the 316 stainless steel strip ideal for high-temperature environments such as furnaces, boilers, heat exchangers, and thermal processing equipment. Its ability to perform under both high heat and corrosive conditions gives it a dual advantage in energy and industrial applications.

Ease of Fabrication

Despite its superior strength, the 316 stainless steel strip remains highly workable. It can be cut, welded, bent, and formed using conventional fabrication techniques, offering manufacturers flexibility in producing custom components and complex designs. This versatility is especially useful in industries that require precision manufacturing, such as medical equipment, food processing machinery, and aerospace components. The 316 stainless steel strip is also compatible with a variety of welding methods, ensuring strong and durable joints that maintain corrosion resistance.

Aesthetic Appeal

In addition to its functional benefits, the 316 stainless steel strip has an elegant, smooth, and shiny surface that retains its polished look even after long exposure to harsh environments. Its resistance to tarnishing and staining makes it suitable for applications where appearance is as important as performance. Architectural facades, decorative trims, kitchen appliances, and public installations often use the 316 stainless steel strip because it provides both a high-end aesthetic and long-lasting durability. Its ability to combine strength with beauty has cemented its place in both industrial and consumer-facing markets.

The unique combination of strength, durability, and corrosion resistance makes 316 stainless steel strip an invaluable material across a wide range of industries. Its ability to perform in harsh environments, coupled with its versatility in fabrication and aesthetic appeal, has solidified its place as the material of choice for manufacturers looking to ensure the long-term performance and safety of their products. Whether you're involved in the construction of marine vessels, chemical processing equipment, or medical devices, 316 stainless steel strip offers the reliability and performance needed to meet the demanding requirements of modern industrial applications. By investing in 316 stainless steel strip, businesses can ensure that their products remain durable, safe, and visually appealing over time, ultimately contributing to greater operational efficiency and cost savings.

https://www.zhonggongtemetal.com/316-316L-Stainless-Steel-Strip.html

http://www.zhonggongtemetal.com

Jiangsu Zhonggongte Metallurgical Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.